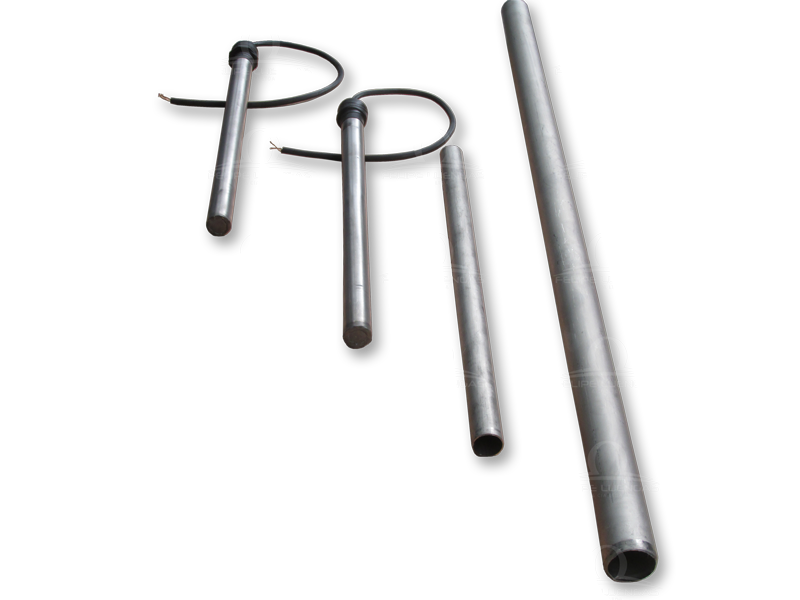

Electroplating:

Immersion heaters with the particularity that they operate partially submerged in corrosive liquids, therefore the case must be highly resistant to corrosion and the terminals located at only one end. Before ordering to manufacture the heater it is advisable to make tests exposing a sample of sheath to the particular acids of each application. Titanium in diameters of 1 "and 1 1/2" and Quartz in 1 "are used for the sheath.

Characteristics:

- Operating temperature below the evaporation point of the medium.

- Heat transfer by conduction and convection.

- Their useful life will be longer if it is guaranteed that they always operate within the environment for which they were manufactured.

Applications:

Chemical baths of:

- Phosphated.

- Degreased.

- Electropolished.

- Nickel plated.

- Fixed.

- Pickling.

- Zinc plated.

- Chrome.

- Colored.

- Polished.